Mike Adams, the Health Ranger, designed the world's first 3D-printable float valve that uses commonly available parts that are easily found in any home (or even scavenged in a war zone). Those parts include a pencil eraser and a paper clip (see below).

Click here to see the full do-it-yourself video of the assembly of these grow boxes.

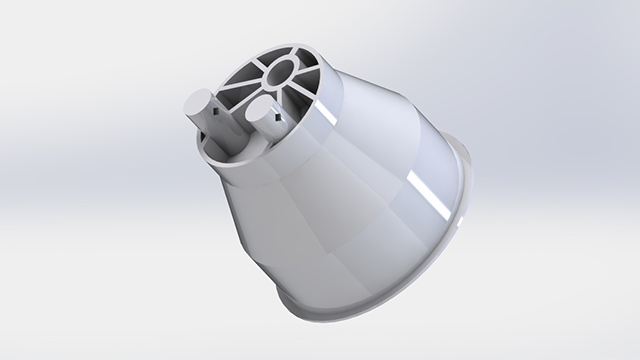

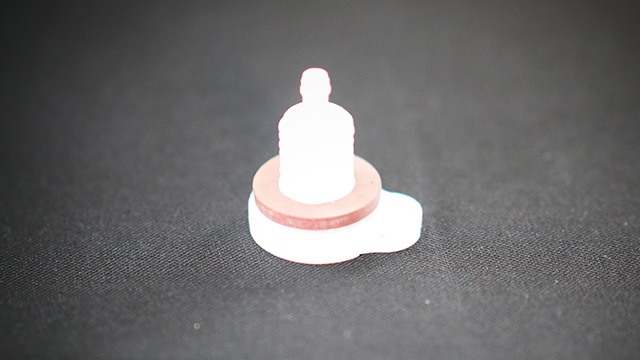

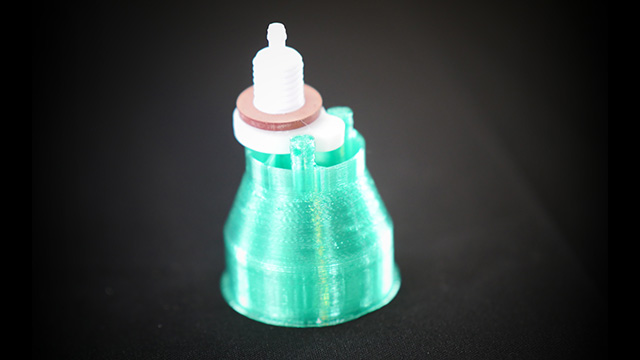

Float Valve Adapter: This part attaches to the vitamin bottle lid to create the float mechanism. It also houses the pencil eraser. This part pivots against the Float Valve Receiver to open and close the water intake hole.

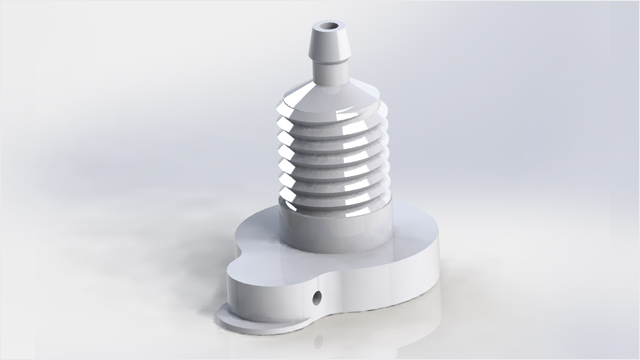

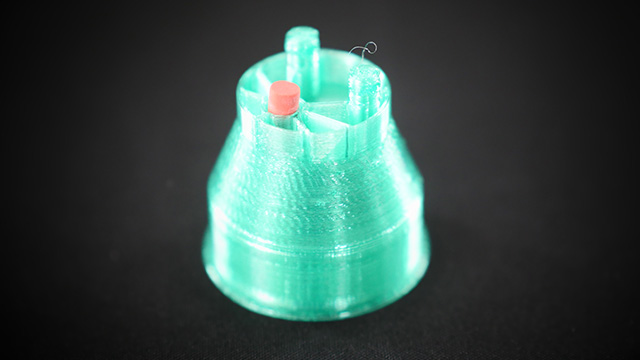

Float Valve Receiver: Contains a small hole at the bottom which is opened or closed by the pencil eraser in the Float Valve Adapter. This part also includes threads so that it can be mounted to the side wall of your grow container and secured using the Retention Nut. Finally, this part also has a drip line nozzle where standard 1/4-inch drip line is attached (RainBird drip line works great). This piece is the most difficult to 3D print and the strength of the top nozzle will be insufficient unless you use t-glase filament and a print nozzle size larger than 0.5mm in diameter.

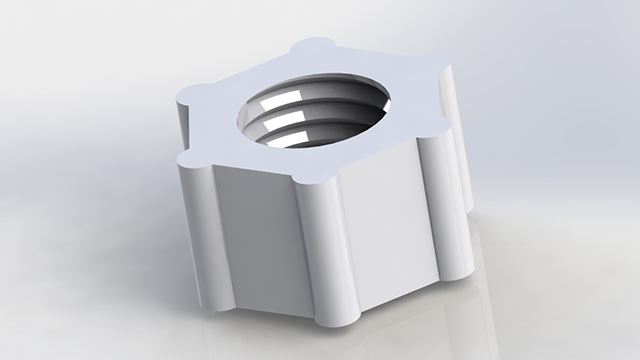

Float Valve Retention Nut: This is a simple nut that screws onto the Float Valve Receive to secure it to the side wall of your grow container. The thread pattern matches the Float Valve Receiver threads.

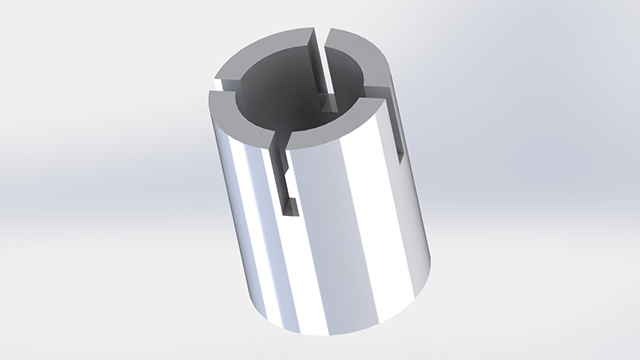

Compression Fitting: An optional part that can help secure the drip line to the nozzle of the Float Valve Receiver. It provides additional pressure to help prevent drip leaks.

Important: If you break off the nozzle when attaching the drip line, it means your nozzle does not have sufficient strength. This is caused by trying to print nozzles in ABS or PLA materials which are very fragile. T-glase is the recommend filament material for this object, and your print nozzle size must be 0.5mm or larger in order to have the layer-to-layer strength ("delamination force") to result in a strong nozzle. T-glase filament is available at www.SupplySource.com. If you have printed this part correctly, you will be unable to break off the nozzle using your bare hands, no matter how hard you try.

At this point, you can test the float valve. There are two functions the float valve must achieve:

Function #1) Allowing water to enter via the water intake hole, but cutting off the water when the float rises.

To test this, simply fill your water reservoir (a separate bucket or pail), attach the drip line hose and allow gravity to push water through the Float Valve. You should see some water entering through the small hole. The speed of this water is not important (it will be slow).

After a few hours, the water level in the grow box should have risen to the point where the float valve presses the pencil eraser to the hole on the bottom of the Float Valve Receiver. At this point, no additional water should enter the grow box. Test this by filling your water reservoir with water (so that the water level in the reservoir is HIGHER than the water level in your grow box) and waiting a few hours. When you come back to check on it, you should see that the water level remains constant in the grow box.

Function #2) Preventing water from escaping the grow box when the grow box is filled with water (this is the starting condition of the grow box when sprouting new plants).

To test this, simply fill the grow box with water all the way to the top. This will force the float valve to close. Now observe the outside of the Float Valve Receiver. Do you see any water leaking out?

If water is leaking out between the nut and the threads of the receiver, this can almost always be solved by applying thread tape to the threads of the receiver.

If water is leaking out of the nozzle hole, this means your eraser has not sealed well against the water intake hole. Double check to make sure your eraser is sticking out of the Float Valve Adapter by 4mm or so.

If you still see leaks, you may have a bad 3D print where water is seeping through the additive layers of the print itself. This is usually caused by failing to use the proper 3D printer filament (t-glase). In our tests, even Colorfabb filament was not 100% leak-proof and allowed water to seep through the layers at a very slow pace. ABS and PLA should never be used to print the Receiver, although ABS can be used for other parts, if desired.

Got a better solution? Help us design an improved float valve and we'll share it with the world on FoodRising.org while rewarding you with $250 worth of UltraClean Super Plant Food. (Yes, we offer product rewards for awesome 3D object designs!)

Posted 3/19/2015

Posted 3/17/2015

Posted 3/10/2015